Long-Term Oil Port Performance

Background

My first Shimano hub gear only lasted two years before failing catastrophically. Dismantling it after failure it was evident that it had let water inside and there was lots of corrosion. It's not a pretty sight, but the full detail (and nasty pictures) is listed on another page.

Modifications

Recalling that good old Sturmey-Archer hub gears work forever, withstanding any abuse as long as they get an occasional dose of oil through the hole in the shell, I have decided to see if I can put an oil port on my new hub.

A month after first putting in oil, there was still some oil mobile within the shell, suggesting that it hadn't all leaked away, which was good. The state of the oil at that stage is described on the oil port page.

Longer Term Performance

After it had been running happily for a couple of months, I left the hub alone for six months.

When it was nearly two years old (almost the age when the first hub expired), and had had six months without any oil top-ups. I thought I'd open it up and see what was inside....

First I took out the oil port plug and set the hub with the hole downwards, to see if any oil would drain out.

After about 45 minutes, a drip was starting to form (it took about 20 minutes for any sign of any oil to appear at the hole). I was actually quite surprised (but pleased) at this - it means there is still free oil migrating around inside the hub.

Wheel off.

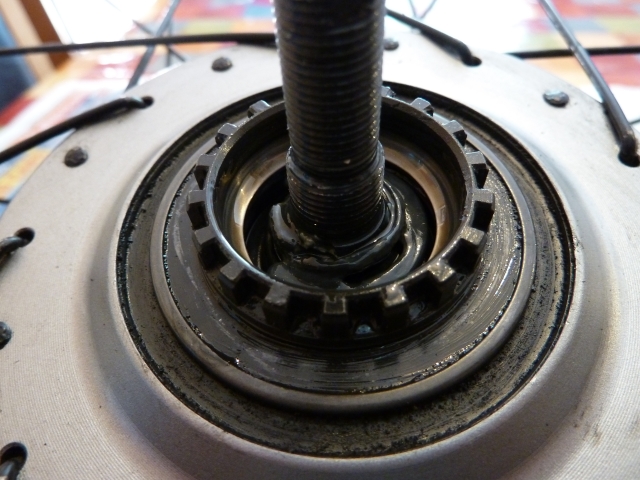

Left side cone off. This is the first glimpse at anything inside ... looking good.

Left side cone and balls look good.

This is the ball-race that is furthest from any oil bath effect in the hub shell. I'm pleased with how oily it all looks.

Left side cup looks good too. Oil obviously gets to here somehow.

The inside of the hub shell is dirty, but it's oily dirty, and no sign of corrosion.

After wiping out the oil from the hub shell, I'm very happy indeed. There is no sign of any corrosion.

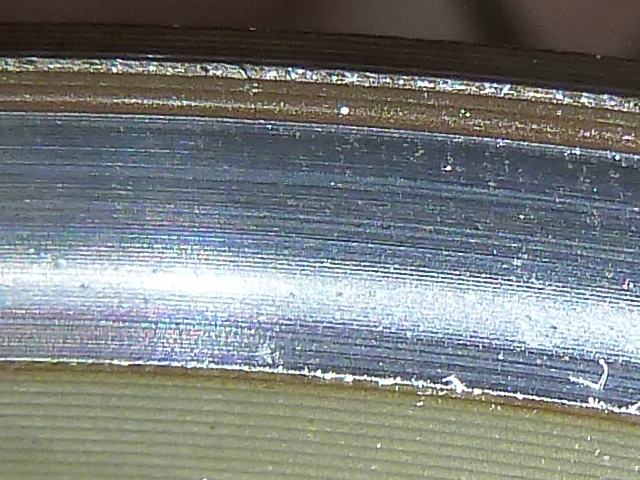

Even close inspection of the races shows everything in good condition.

Even very close inspection.

As you'd expect with the cups and races in that condition, the mechanism of the innards is in good condition.

The ball race and cage that failed in the first hub is still in as-new condition.

Although the whole mechanism is oily, there are traces of the original grease. I don't see any need to clean them out.

Interestingly, having set the wheel with hub shell aside while I investigated the mechanism, oil drained down to the bottom of the shell. This despite my having wiped out the bulk of it (as in the photos above). It seems like tenacious but nicely flowing stuff.

When re-assembling it, red tape came to hand quicker than green!

Conclusions

I'm very, very pleased with these findings.

The condition inside the hub is excellent, really good-as-new. Whether that is down to my oil port modification or not, I'm now happy that I have a hub gear that lives up to its low-maintenance promise.

I actually think, however, that the oil port contributes to that condition - the oil clearly distributes round the innards, and does not escape even given six months without top-ups.

Leak!

After re-assembling, I put 20ml of oil back in. This was with the mechanism wet with oil to start - so possibly 25ml or so of oil inside in total. That didn't leak in the 36 hours it then sat in my garage, but after ten hours at work there was a small oil-leak on the floor under the hub. The difference, I think, is that at work the bike sits leaning over at about 30 to 45 degrees to vertical, with the left side (brake side) down. I conclude that 25ml is too much if you're going to lean the bike over like that. It also suggests that if you do need to lean the bike, leaning it chain-side-down might be better.

My conclusion - because of how I store the bike leaning over, I shouldn't put more oil in than draining it and adding 10ml. I don't think this minor leak alters my view that the oil port is worthwhile. If you routinely need to lay the bike down on its side, however, it might mean it's not the thing to do for you.